Warning: Undefined array key "query" in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Deprecated: preg_match(): Passing null to parameter #2 ($subject) of type string is deprecated in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Warning: Undefined array key "query" in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Deprecated: preg_match(): Passing null to parameter #2 ($subject) of type string is deprecated in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Warning: Undefined array key "query" in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Deprecated: preg_match(): Passing null to parameter #2 ($subject) of type string is deprecated in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Warning: Undefined array key "query" in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Deprecated: preg_match(): Passing null to parameter #2 ($subject) of type string is deprecated in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Warning: Undefined array key "query" in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Deprecated: preg_match(): Passing null to parameter #2 ($subject) of type string is deprecated in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Warning: Undefined array key "query" in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Deprecated: preg_match(): Passing null to parameter #2 ($subject) of type string is deprecated in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Warning: Undefined array key "query" in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Deprecated: preg_match(): Passing null to parameter #2 ($subject) of type string is deprecated in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Warning: Undefined array key "query" in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Deprecated: preg_match(): Passing null to parameter #2 ($subject) of type string is deprecated in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Warning: Undefined array key "query" in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Deprecated: preg_match(): Passing null to parameter #2 ($subject) of type string is deprecated in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Warning: Undefined array key "query" in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Deprecated: preg_match(): Passing null to parameter #2 ($subject) of type string is deprecated in /home/thedigitalhacker.com/public_html/us/wp-content/plugins/amazify/amazify.php on line 139

Traditional mills and routers are big handled or table-mounted spindles for analogue carving work; the CNC router refines the process by introducing pinpoint accuracy in three axes and allowing you to make end-use and, more crucially, sellable objects right before your eyes. And, maybe best of all, you can get a nice one for just $300.CNC routers are an excellent item to consider for any maker’s workshop in order to bring the creativity within you out into the open. Cutting woods, metals like aluminium (best cnc router for aluminium), and other materials with diverse textures and structures, the CNC router can accomplish some things that 3D printers can’t.

A CNC machine is a computer-controlled motorised manoeuvrable tool and, in certain cases, a motorised manoeuvrable platform that follows particular input instructions.

The CNC machine receives instructions in the form of a sequential programme of machine control instructions such as G-code and M-code, which are subsequently executed. A person can write the programme, but it is far more likely that it will be generated by graphical computer-aided design (CAD) and/or computer-aided manufacturing (CAM) software. The part to be produced is “sliced” in 3D printers before the instructions (or programme) are generated. G-Code is also used by 3D printers.

CNC is a significant advance over non-computerized machining, which requires human control (e.g., using hand wheels or levers) or mechanical control using prefabricated pattern guides (cams). The design of a mechanical part and its manufacturing programme are highly automated in modern CNC systems. CAD software is used to define the mechanical dimensions of the product, which are then converted into manufacturing directives using CAM software. The generated directions are then translated (through “post processor” software) into the exact commands required for a specific machine to manufacture the component, and then loaded into the CNC machine.

Because any one component may necessitate the use of a variety of tools – drills, saws, and so on – modern machines frequently integrate numerous tools into a single “cell.” In other setups, a variety of machines with an external controller and human or robotic operators transfer the component from machine to machine are used. In either case, the succession of procedures required to manufacture a part is highly automated, resulting in a part that nearly resembles the original CAD drawing.

The mills themselves evolved in tandem with the controlling hardware. As a safety measure, one change has been to enclose the entire mechanism in a huge box, with additional safety interlocks to guarantee the user is far enough away from the working piece for safe operation. The majority of modern CNC systems manufactured nowadays are entirely controlled by electronics.

FEATURES OF CNC machine

1-Lubrication system- It’s worth noting that a machine tool that follows a regular maintenance and lubrication routine can provide long-term reliability. It is a well-known fact that insufficient bearing lubrication leads to early bearing deterioration. In addition, track rails might be damaged by insufficient lubrication.

2-Boring heads-Boring heads are an essential component of CNC machines used in the woodworking industry. It’s a well-known truth that the woodworking business needs to mass-produce designs in a variety of forms and sizes.

3-Transitivity-After troubleshooting and confirming the test cutting process, the CNC machines’ transitivity can be used to save valuable time while also ensuring quality. Furthermore, the procedure can be used as a template for the processing of comparable parts in the future.

4-Spindle options-When it comes to spindles, both 3-axis and 5-axis CNC machines have a wide range of possibilities. In the world of CNC machining, the HSD and Perske spindles are already a major hit. They are effective and can carry heavy loads while maintaining the highest level of precision.

5-Automated tool-Automated tool length setters can improve the efficiency of 3-axis and 5-axis CNC machines. The technologies for measuring length are quite precise. Furthermore, they contain a single M-Code that, in an automated setting, executes the tool selection.

ADVANTAGES OF CNC MACHINE

1-Capability-CNC machines, when used in conjunction with modern design software, produce results that manual machines cannot match. Even the most talented engineers couldn’t duplicate what advanced software can achieve with CNC machines using traditional machinery.

2-Less labor-CNC machining necessitates the use of fewer people to complete industrial activities. One trained operator can operate numerous autonomous CNC machines, and one programmer may put the necessary designs into them.

3-Lower costs-High speed, efficiency, specialisation, precision, and, most importantly, less work hours all contribute to a stronger bottom line for your company. Lower costs can therefore be used to gain a competitive edge and reinvest in the firm.

4-Better safety-A safer atmosphere comes with a faster production process and consistent pieces. While CNC machines have operators, they are kept at a safe distance from the sharp tools, whereas traditional-manual lathes, drills, punches, and other equipment have operators who are in direct touch with the implement.

5-Versaitility- CNC machining can make almost any component you can think of. Special features and attachments, including touch screens and automated tool changeover, are included in some models to help speed up and simplify the manufacturing process.

Disadvantages of CNC machine

1-Price- CNC machines are more expensive than manual machines, yet costs are gradually decreasing.

2-Machines- The CNC machine operator just requires rudimentary training and skills, which are sufficient to supervise multiple machines. Engineers used to need years of training to run centre lathes, milling machines, and other manually driven devices in the past. As a result, many of the traditional talents have been lost.

3-Machines-When compared to manually operated equipment, CNC machines require less people. Investment in CNC machines may result in job losses.

4-Abilities-Another drawback that some machinists see with the CNC process is that it tends to obviate the need for traditional manual abilities. Along with them go the math and science abilities honed by people who learn to handle lathes, mills, drills, and other hand-operated machines during years of instruction.

5-Loss-While CNC machining has opened up a plethora of new prospects for all types of organisations, it has also resulted in less traditional machining and, as a result, some job losses. Most experts, on the other hand, do not believe that manual skills would become obsolete.

Here is the top 13 best cnc machine

1-Shapeoko 3 XXL

The Shapeoko 3 XXL, presented by Carbide 3D store, may blow it all away at a reasonable price that works best for you while handling the real work in your workshop. It’s great and perfect, sturdy yet precise, with a basic design and a large cutting area to help you take your ideas to the next level. Now it’s time to weigh the pros and cons of pricing vs. quality and capability. It is a very reasonable price for the best CNC wood router on the market that can provide you with an industrial-like experience, and it works well for both business owners and hobbyists who are willing to spend a lot of money in exchange for a lot of features.

The Shapeoko 3 XXL is a fantastic professional Desktop CNC router that you should consider without spending a fortune. If the price is a little too much for you, the Standard size version is roughly $600 less expensive than the XXL, while the XL is $1,499 but has fewer amenities than her twin sister.

FEATURES:

1-User friendly-It is a big CNC router kit that is simple to assemble using the precise step-by-step instructions provided, and to run using user-friendly CNC software that streamlines the CNC process so that you can get the most out of it.This CNC router kit not only puts a massive 838 x 838 x 76 mm cutting area in your hands, but it also includes additional instructions to help you master the process.

2-Price-The Shapeoko 3 is marketed as a workshop machine that can chew through actual work while remaining inexpensive. We’re inclined to trust Carbide 3D’s word for it, given the router’s enormous popularity and the specifications on paper. The Shapeoko is available in a variety of configurations that increase the cutting power and area, starting at $1,099 for the base kit.

3-Functioning-An industrial-grade motion controller running on the open source GRBL firmware sits beneath the Shapeoko 3’s functioning aluminium and 10-gauge steel frame. The machine’s acceptance of G-code commands ensures widespread CAM software compatibility.

4-Design-The Shapeoko 3 standard model has a cutting area of 406 x 406 x 76 mm, allowing for 3D designs. The Shapeoko XL extends the cutting border to 838 x 406 x 76 mm, while the Shapeoko XXL extends it to 838 x 838 x 76 mm. If owners of the Shapeoko 3 want to upgrade to the XL or XXL versions, they can purchase upgrade kits.

5-Router-The standard Shapeoko 3 kit comes with Carbide 3D’s design and control software, Carbide Create and Carbide Motion, and is designed to provide a router-touting user everything they need to get up and running and cutting in no time.

PROS:

- A gigantic cutting area

- Amazing detailed assembly guide

CONS:

- Heavy-duty machinery that necessitates the assistance of two people to fully assemble.

- You’ll need a large horizontal workstation to place the machine on.

2-Carbide 3D Nomad 883 Pro

Carbide 3D offers the Nomad 883 Pro, which is smaller in comparison to the Shapeoko 3 XXL. With a working area of 8” (X and Y), 3” (Z), and a spindle speed of 2000-10,000 RPM, it is more suitable as a mill machine with more precise cuts in many types of material. However, if you are looking for a larger sized product, this is not the one for you. The capacity of the Nomad to work with any operating CAM software you like is one of the wonderful possibilities for you to be delighted with. If you are unfamiliar with MeshCAM, Carbide Create, or Carbide Motion, or any of the other softwares that come with it, you are not confined to these.If you want to use any of the apps listed above, the operating systems that function best with it are Windows 7, 8.1, 10, and OS X 10.9, 10.10, and 10.11. This desktop CNC machine costs $2499, which is a reasonable price for all of the capabilities and the quality of the cutting work it performs. The Shapeoko 3 XXL is a tad on the lean side, but the Nomad 883 Pro is more robust and entire. However, for minor job assignments, this is a good option.

FEATURES:

1-Fully enclosed-To keep dust and noise out, the Nomad 883 is completely enclosed in either HDPE or Bamboo. With the shell closed, the Nomad may be placed anywhere in your house or business without creating a mess. All you’ll need is a little shop vac.

2-Tool length measurement- Calibration tool length on a desktop CNC machine is usually a problem because they lack the automation inherent in larger industrial machines. We created an accurate and simple approach to automatically measure the tool length before cutting anything for the Nomad. It’s all done throughout the cutting process because it’s entirely integrated with our machine and software.

3-3D cam included-MeshCAM, an easy-to-use 3D CAM software, is included with the Nomad 883 Pro. MeshCAM builds a toolpath from an STL file from your CAD programme with very little input from you. We’re not aware of any other method for generating a 3D toolpath.

4-Support for Windows Mac-All of our applications is compatible with both Windows and Mac. We believe that you should be able to use whatever computer you desire, and we do everything we can to ensure that you have access to both.

5-Fits on your desktop-With a footprint of 20 × 20 inches, the Nomad 883 Pro may be used on practically any standard desktop or bench top. We made a few tweaks to the Pro to trim down the design without affecting the cutting area.

PROS:

- Made in california and has great features

- 3d cam is included

CONS:

- It is expensive

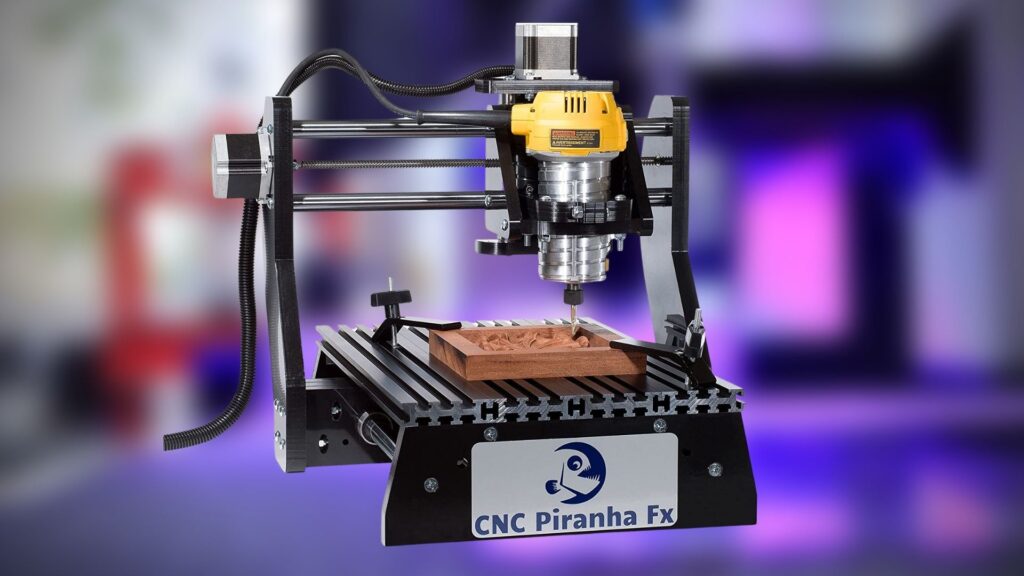

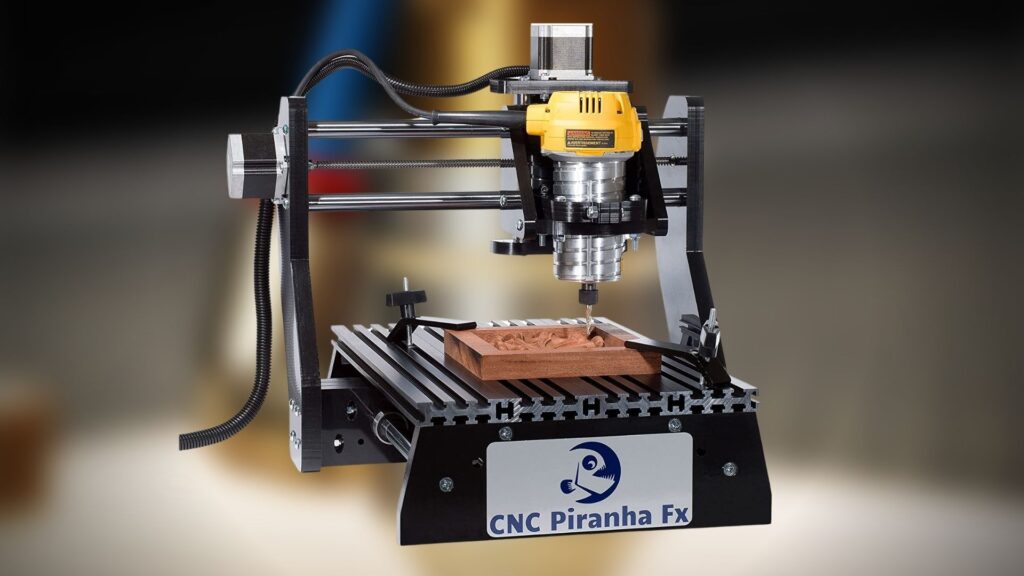

3-Next Wave Automation CNC Piranha XL

The Piranha XL CNC from Next Wave Automation is a fantastic CNC for wood engraving and small piece cutting for woodworkers, but it can also operate on other materials. The Piranha XL desktop CNC has a touchscreen controller that may be used in conjunction with a USB controller, eliminating the need for additional equipment and allowing for continuous generation using the software. For a better working experience, the router has auto-edge and auto-sensing features. Piranha XL does the same job as the CNC Shark HD but for a lot less money; a Piranha XL will set you back $2500 on Amazon.Piranha XL can cut any material that a cutter can, although it prefers to deal with wood, plastics, and soft metals like aluminium. Simply ensure that you’re utilising high-quality router bits. This machine has a lot to offer, with a working space of 12 x 24 x 4 inches.

FEATURES:

1-Ideal-The All-New CNC Piranha XL comes with an extra-large table that’s ideal for carvings, plaques, ornamental boxes, and precise parts made of wood, soft metals, or plastics. Simply use the bundled VCarve Desktop V8 Design software on a PC computer with a USB 2.0 connector to design your project.

2-Performance- The Piranha FX, like the NWA Shark versions, may be used with Porte-Cable, Dewalt, Bosch, and other similar palm routers. The unit comes with a 14-inch V-router bit and is powerful enough to give precise and accurate results for the majority of applications. Its accuracy is exceptional, especially when using the 3D carving module. It makes use of the NWA 3D digital touch probe, a 3D duplicator that can scan/trace a 3D image and duplicate/reproduce the object down to the tiniest features – it can copy an object down to 0.001-inch resolution.

3-Working area-This Piranha FX model has a working surface of only 12 x 13 x 3 inches, thanks to its tiny design. It’s a compact work surface that’s perfect for small-scale tasks like ornamental boxes and carvings, as well as wooden plaques, plates, precision pieces, and carvings. The table itself is built of an aluminium slotted table track. It enables interlocking, allowing for easy clamping of workpieces in any position.

5-Materials-This New Wave Automatic CNC model can work with a wide range of materials, including solid wood, MDF, composite plywood, plastics, stone, and soft metals like aluminium, thanks to its three separate modules. It can also be used to engrave circuit boards, but only to a certain extent. Because the machine is stable but not robust, it cannot handle hard metals or heavier materials.

PROS:

- It can carve and engrave with great precision and detail.

- It is capable of working with a wide range of materials.

CONS:

- It just has a modest workspace.

- The router must be purchased separately.

- Hard metals are not compatible with the item.

4-Maslow CNC

Maslow CNC is a $500 CNC router kit that includes everything you need to get started. With a massive working space of 4’x 8′, you’ll have a great time engraving and woodcutting a variety of things ranging from furniture to wooden art pieces. You may unleash your inner creativity, offer it to the world, and get compensated for it for a very little price. Maslow’s users raved about how simple it is to use, thanks to user-friendly software and straightforward training. This machine is built as a kit that is simple to ship, assemble, and monitor, providing you with a fantastic experience for your projects.One of the most appealing features of this CNC router is the ability to shrink or expand your working area by creating your own smaller or larger frame for the Maslow, which works perfectly normal even the software and calibration process will take this new size into account and adjust the working process accordingly.

FEATURES:

1-Function-The Maslow CNC also includes unique features such as Z-axis capability. Cutting out a treehouse, furniture and fixtures, boats, and just about anything else is a breeze using Maslow’s Machine. Another important element of the Maslow is that the designs may be digitally shared with others.

2-Reliable- Maslow’s Hanging CNC Machine is a classic engraving wood milling machine that allows users to cut wooden products with precision and accuracy using a CNC software.

3-Durable-The machine is strong enough to cut out anything that a typical hand router can cut out. The tool may be used to carve out and shape hardwoods, hard plastics, plywood, MDF laminate, and other materials.

4-Easy to use-For only $500, you can obtain the whole Maslow’s kit! Furthermore, the gadget is simple to put together. On Maslow’s website, there is a user manual that clearly explains how to put the kit together.

5-Adjustable- The Maslow router can carve a surface that is 4×8 feet in size. The machine’s cut depth can be adjusted.

PROS:

- It is cheap

- It is compact and effective.

CONS:

- The feed rate is slow

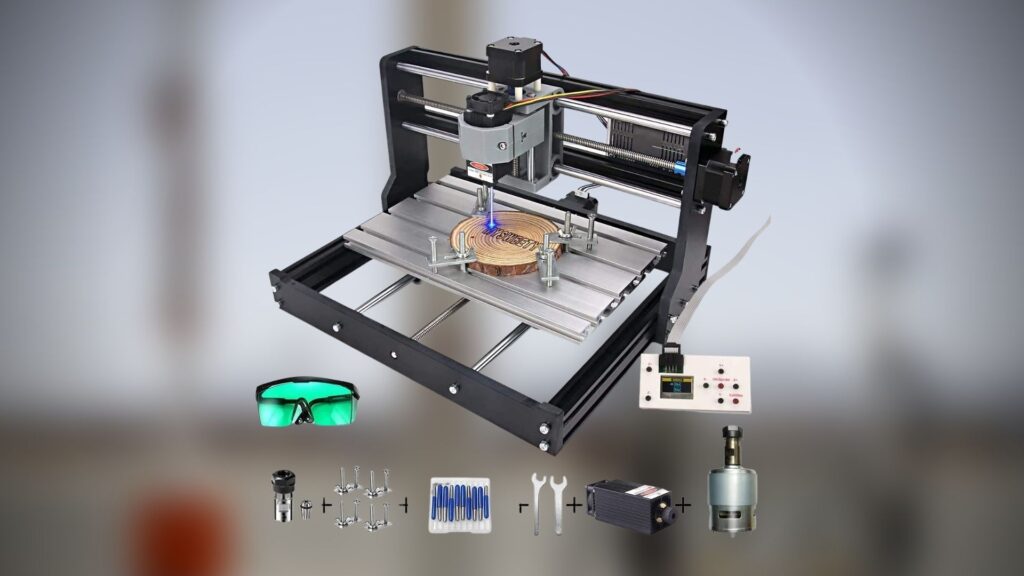

5-MYSWEETY 1610 CNC Router Kits 1610 GRBL Controller Wood Carving Milling Engraving Machine

On Amazon, the MySweety 1610 CNC kit is very popular; in terms of quality-price ratio, this CNC router ranks at the top; for less than $200 (with the spindle), this 3-axis CNC machine can truly perform a decent job. If you’re seeking for more affordable solutions, take a look at this list of the top cheap CNC routers. This machine arrives in your workshop as a kit that is simple to put together; you can find lots of guides online to assist you with the task at hand. It’s fun and interesting to put this tool together and see it work; simply play about with it and have fun.If you wish to cut wood, plastics, or other materials, you should also consider purchasing bits. The software will be figured out later. The SWEETY 1610 CNC Router is a desktop type of machine with a 160 x 100 x 45mm engraving area, so it’s only ideal for little projects. It’s the best choice for a budget-friendly CNC machine.

FEATURES:

1-Price-If you buy a 1610 milling engraving machine, you’ll get a free power supply. Just add the power supply and the 1610 milling engraving machine to your cart before checking out.

2-Area-160 x 100 x 45mm working area; GRBL Control software. It is compatible with Windows XP, Windows 7, Windows 8, Windows 10, and Linux. Wood, plastic, acrylic, PCB, PVC, and soft metals such as copper and aluminium can all be carved.

3-Motor: new Nema 17 stepper motor; spindle: high-speed 775 spindle motor Using a specially built engraved integrated mainboard and tailored software, the functions are far superior to those of comparable devices.

4-Warranty-A one-year money-back guarantee is included.

5-Design-With professional GRBL control software, this DIY CNC engraving machine is specifically made for DIY pleasure, study, and research, providing you an extreme portable experience.

PROS:

- Cheap

CONS:

- Difficult to install

6-Taishi Desktop CNC Router

In terms of mechanism characteristics and technology, the Taishi Desktop CNC router shares a lot of similarities with the JFT machine right away. Taishi router, on the other hand, is not built for more demanding jobs. Taishi Desktop CNC is more of a hobbyist first-time user type, but the frame has a sturdy build of the table and gantry that prevents shaking and creates no noise when operating, which is also a big bonus. This tool is a fantastic sturdy machine with an air-cooling system to keep the spindle in good working order even at speeds of up to 24000 RPM.If you’re eager to put your money to good use while studying and improving your talents, you can go for this attractive gadget.

FEATURES:

1-Equipped-The Taishi Desktop CNC Router is a solidly constructed 3D drilling, milling, and engraving equipment with a tiny footprint. It’s ideal for a hobbyist or craftsman who works with little materials.

2-Accuracy-Once properly levelled and mounted, the CNC router is capable of cutting to 0.04mm accuracy and resetting to 0.05mm.

3-Durable-incorporates an external 3-axis control box and aluminium frame materials, resulting in a long-lasting and stable CNC router.

4-3D-Large 3D engraving in MDF board, acrylic, soft wood, PVC, and natural wood is possible using a CNC router.

5-Lifespan-The machine’s thicker and reinforced body ensures safe transit and a longer lifespan.

PROS:

- Easy to set up

- Small footprint

CONS:

- It is heavy

7-CNC Piranha FX Desktop Router

Piranha FX is the base model produced by Next Wave Automation, and it is more ideal for hobbyists and learning purposes than the CNC Piranha XL router machine. When it comes to the size necessary for high-intensity production, this one falls short, since it’s a quite small machine with a 12 x 18-inch table and 12 x 13 x 3 inches of XYZ travel for you to work on.Piranha FX also includes similar powerful features like the touchscreen controller and all of the other operational options available in the more expensive Shark and Piranha XL models at a more inexpensive price to keep your wallet from shrinking only for a hobby oriented machine to utilise.

FEATURES:

1-3D Printing-Create your own little 3D item, then utilise the printing module and spooled plastic “thread” filament to duplicate components, create figures, and design or fabricate anything. With the Vectric VCarve Desktop 8.0 software provided with Piranha FX and their own PC or laptop, users can print 3D models.

2-Less engraving-Piranha FX will engrave flat sheet materials like wood, paper, plastic, or fabric by adding a laser to the chuck of the machine’s palm router. Here’s how to use shaded realism to transfer pictures or other graphics to sturdy materials. The laser isn’t designed to cut all the way through.

3-Carving Module-By adding a laser to the chuck of the machine’s palm router, Piranha FX will engrave flat sheet materials such as wood, paper, plastic, or cloth. Here’s how to transfer photos or other visuals to durable materials using shaded realism. The laser isn’t meant to go all the way through the material.

4-Controls-The machining process is controlled by computer-controlled stepper motors in the CNC Piranha FX. For routing, the machine’s XYZ travel is 12′′ x 13′′ x 3′′, and for 3-D printing and laser engraving, it’s 12′′ x 12′′ x 3′′. Clamping can be done anywhere on the aluminium work table thanks to T-track slots that run the length of it.

5-Available-Piranha FX had not yet been made available to the public. However, if you’ve been waiting for it, the time has come. It’s now available at a few woodworking shops, including Rockler.

PROS:

- Easy to set up

CONS:

- Expensive

8-3018 GRBL MYSWEETY DIY CNC Mini Desktop Router Kit

3018 GRBL DIY CNC comes in a kit that is largely made of aluminium and comes with a simple step-by-step guide on how to put it together. It also features a durable and more intact frame to support the entire manufacturing process.

This little CNC carving and milling router has a price of 205$, making it a good product to buy if you can’t afford a more expensive one, and the web reviews are proof of that, giving you that extra push to go for it.

This CNC router with three axes (X, Y, and Z) has an engraving area of 300 x 180 x 45mm and a spindle that spins at 7000 rpm. However, due to its small size, it may provide an issue. As you can see from the above 3018 MYSWEETY offers you fantastic value for your money in return for the 205$ you will invest.

FEATURES:

1-Updated Version: The CNC 3018-PRO is a more advanced version of the CNC 3018. GRBL is the control programme. 30x18x4.5cm working area Spindle motor: 775 spindle

2-Module-Comes with a 7W 7000mW module that can be made out of carved wood, bamboo, paper, ivory, leather, flammable plastic, PCB, ceramic/stone, metal surface paint, metal surface plating, and other materials. Metal, iron, glass, 201/304 stainless steel, jewellery, or silver cannot be worked on.

3-Manual-The major two advantages of using an offline controller are that you don’t have to connect your computer and you don’t have to download anything. Manually set the X, Y, and Z axis as the engraving start point, open or close the spindle, and open or close the cooling fan.

4- Controls-choose entrance in a plastic body with a profile, compact size, light weight, USB interface, GRBL control systems, and learn to use the preferred entry in a plastic body with a profile.

5-User friendly-Another advantage of this machine is that it is easy to operate and is a fantastic choice for beginners. It comes partially built, making it simple to put together on the first usage, and it can work on a number of materials

PROS:

- It has a Good quality

CONS:

- Expensive

9-JFT CNC 3040 CNC Router/Milling Machine

With its water-cooling system, the JFT CNC 3040 offers you industrial-like characteristics directly in your home. This Chinese CNC router machine is ideal for the production of high-intensity levels, allowing you to get more work done faster and manage longer continuous operation times. Consider this option if you’re looking to create a serious, results-oriented commercial product that necessitates nonstop work for long periods of time.The JFT CNC 3040 offers a 22 x 14-inch cutting surface, 11.8 x 15.74 x 3.5 inches of XYZ travel, a spindle speed of up to 24000 RPM, and is compatible with a wide range of CNC software, including ArtCAM and CopperCAM Software. The price is set at 2175 dollars, which is a good deal if you’re ready to put in the time and effort now to reap the benefits later.

FEATURES:

1-Performance-When compared to smaller CNC machines, the CNC 3040 is unrivalled. When it comes to quality, it can cut everything from wax to metal with great precision. However, there is a lot of study that has to be done with a stronger machine that can cut metal.

2-ZProbe-There’s no need for manual zeroing now that the Z probe is included in several purchase options. To begin cutting on a smaller CNC machine, you must first place the bit in relation to the workpiece. The Z probe removes some of the complexity from the equation.

3-Control box- The CNC 3040’s power supply and control board are separate, unlike many other desktop machines that have connected power supplies. This enables a reliable emergency shutoff, simple configuration modifications, and code uploading.

4-Easy upgrade-It’s as simple as replacing the holder to upgrade the spindle. Other modifications to consider include a vacuum boot for dust collection and a drip lubrication system. Both prevent the machine from overheating or becoming stuck.

5-Upgradable-Because the CNC 3040 has a bigger frame, the spindle holder can be swapped out. You can get a stronger spindle by replacing the spindle holder with a larger one, which allows you to cut through tougher or softer materials more easily.

PROS:

- Works smoothly

CONS:

- Not that efficient

10-CNC Shark HD 4

The Next Wave Automation’s CNC Shark HD 4 is a high-performance CNC router with amazing features to consider for any CNC router that needs to be reliable and consistent for commercial use. The interlocking aluminium table and reinforced gantry are excellent features for reducing wobbling during operation. This machine also gets a big thumbs up for its water cooling system. It is presently out of stock; however, when it becomes available, you can find it on Amazon.

FEATURES:

1-Designs-The Shark HD4’s general stiffness and stability are the first things that strike you about it. The gantry is built of thick aluminium plate and polyethene, and the bed is made of thick extruded aluminium with many grooves for clamp attachment. It’s a solid and steady setup that eliminates the swaying and backlashing that plagued prior Shark models, particularly when carving metal and other relatively hard materials.

2-Performance-The Piranha FX, like the NWA Shark versions, may be used with Porte-Cable, Dewalt, Bosch, and other similar palm routers. The unit comes with a 14-inch V-router bit and is powerful enough to give precise and accurate results for the majority of applications. It’s perfect for cutting out delicate forms or completing detail-oriented jobs like carving/engraving a bespoke circuit board because of its exceptional accuracy.

3-Work area-The CNC Shark HD4 has a work surface of 25 x 25 x 7 inches, which is nearly four times larger than the company’s basic X-Carve model. That’s a huge workplace, and it offers up a lot of possibilities in terms of projects you may work on. More elements can be cut from larger workpieces, full-size signs can be made, and even carved panels can be finished in a single session.

4-Materials-During heavy cutting, the Shark HD4’s stiff interlocking aluminium table, robust gantry, and overall structure, which includes thick steel shafts, lead screw, and adjustable bearings, provide stability.

5-Usability-The CNC Shark HD4 comes with a touch-screen pendant as a handle control, which is convenient because it eliminates the need to connect to a computer and saves space over a bulky control box.

PROS:

- It can cut precise components out of a variety of materials.

- With each pass, a large amount of material can be removed.

CONS:

- It’s big and bulky, and it takes up a lot of room.

- Over time, the pendant may begin to malfunction.

11-Pocket NC

When working with aluminium, you need a machine that is built to last and has a lot of power, which is why we propose Pocket NC. This router has five axes and a spinning metal frame that allows you to mould the craft into whatever shape you wish. Pocket NC is available for 4900$, which is a very reasonable price given its characteristics.Pocket NC can carve wood, plastics, steel, aluminium, and other metals for more intricate small-scale item fabrication. The spindle is also included in the pricing and has a speed range of 2,000 to 10,000 revolutions per minute. If you need to carve aluminium, then this is the machine for you.

FEATURES:

1-Quality-Pocket NC creates high-quality 5-axis desktop CNC milling machines for commercial, educational, and personal applications.

2-Material-The Pocket NC 5 Axis Desktop CNC Mill V2-10 can cut materials up to G5 titanium hardness, however it works best with delrin, aluminium, and softer steels.

3-Tools-Before finishing the component, the machinist can use an end mill type cutting tool to machine away huge amounts of material in a “Roughing” cycle.

4-Operator-For the operator or programmer, pocket milling toolpath parameters in a CAD/CAM product will include information regarding Roughing and Finishing tools, Pattern selections, Cutting Direction options, toolpath cutting angle, and Step Over percent input fields.

5-Impact-This type of toolpath can have a significant impact on the final result of a part. The type of pocket milling toolpath used can also influence how long it takes to produce a product.

PROS:

- Amazing work

CONS:

- Expensive

12-Bobscnc E3

When you order a Bobs CNC machine, it will arrive in bits. It’s a home-built kit made of wood that’ll serve as a terrific kickstarter or student CNC machine for you. The cutting area of this Desktop CNC router kit measures 17.7 x 15.3 x 3.3 inches, which is quite large! The cost is $698, which is reasonable for a DIY kit. Keep in mind that the customer service is very highly rated. Bob’s CNC priming material is constructed of wood, making this CNC router an environmentally friendly machine with plastic joints. For those wishing to get their feet wet in DIY CNC engraving and cutting, putting together a bobscnc router is a fun activity to accomplish.

FEATURES:

1-Laser cut frame-It’s important to understand that this is a professional tool that’s only available to woodworkers or amateurs. The merchandise is essentially a two-in-one package, with a router that is one of the greatest computer numerical routers (CNCs) on the market and an engraving kit that can engrave anything on a material.

2-Rail system-Because it is not a manual router, the cutting head and router must communicate via a rail system. The BobsCNC E3 CNC router engraver kit includes an SG20 rail system. It’s one of the top systems on the market right now.

3-Belt drive-There is a GT2 belt drive on the X and Y axes of this kit (of course you need a belt drive to make this thing move from one to the other side). When compared to its competitors, the GT2 drive is the best for the job because it has a larger load bearing capacity and torque.

4-Handle easily- When it comes to doing a task, the task itself is not everything that matters. It’s also crucial to consider whether you can complete the task while conserving time, space, and/or money. Because this router is smaller than other CNC routers, it is easy to handle.

5-Lightweight- It’s lightweight construction (26 pounds) and assembled measurements of 25” x 25” x 19” make it simple to set up and relocate to any location.

PROS:

- TWO in one lightweight powerful engine

CONS:

- Not a hardcore CNC machine

13-Ooznest Workbee

The Ooznest Workbee is a British-made CNC machine with a stellar reputation, with over 2,700 customer ratings on Trustpilot giving it a 4.9 out of 5 rating. That informs you a lot about the kind of service this organisation provides. The Workbee is a product that comes in a variety of sizes, including 300 x 270 mm, 550 x 520 mm, 550 x 770 mm, 800 x 770 mm, 800 x 1270 mm, and 1300 x 1270 mm workspaces.As a result, Ooznest can offer the Workbee in a number of price ranges and sizes to accommodate a wide range of workshop and job needs. It’s a great plus that you don’t have to pay for anything bigger than you truly need.

FEATURES:

1-Quality-To maximise the CNC experience, Ooznest employs several high-quality technology and internals. The Workbee is equipped with a Duet 32-bit mainboard, five TMC2660 stepper drivers, and a screw-driven motion, and it works with Cut2D, VCarve, and Aspire software.

2-Price-It’s also reasonably priced for a computer of this calibre, with costs ranging from $1,730 to $2,200. As an added benefit, consumers rave about the Workbee’s instructions and packaging, which make the assembly process a breeze.

3-Size-It comes in a variety of sizes (more on that later), but each Workbook can cut to a depth of 25 mm with 0.1 mm accuracy.

4-DIY-You will have to assemble the Workbee totally by yourself. Assembling such devices can be a pain, but Ooznest’s packaging, labelling, documentation, and build guidelines appear to have garnered a lot of praise.

5-Software-For your new Workbee, Ooznest offers a few distinct software alternatives. First and foremost, the machine control software is free and pre-installed, so you don’t have to worry about that; however, you do have an option with the CAM software.

PROS:

- Excellent customer service

CONS:

- Works slowly

CONCLUSION

Above we have mentioned some best CNC machines, and for the best experience you can choose Pocket NC as it comes with an amazing quality or you can also find CNC Shark HD 4 as it has amazing work potential.

People Also Look For:

– Best Pellet Stove